Hangcha Electric Lithium-ion End Control Rider Pallet Jack

The A Series Lithium-ion End Control Rider Pallet Truck is an ideal tool for loading, unloading, and handling palletized goods in warehouses and workshops.

- 8,000 lb. Capacity

- Ergonomic Tiller Head

- LCD Interactive Display

- CANBUS Operating Handle

- High Strength Load Backrest

STANDARD FEATURES

- Curtis AC Controller

- Anti-Skid Pedal Pad for Standing Operation

- Electromagnectic Brake

- High Performance PU Driving Wheels

DESCRIPTION

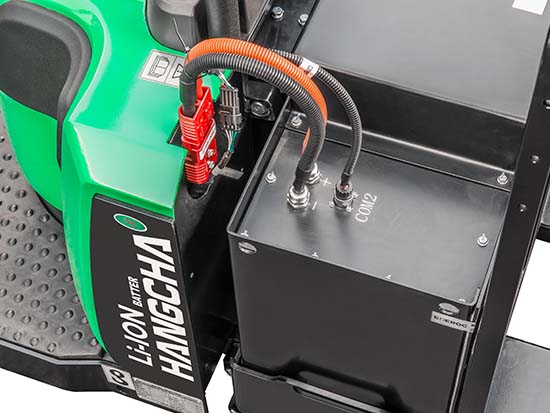

The Hangcha A Series Lithium-ion End Control Rider Pallet Jack uses innovative and reliable batteries manufactured by CATL. These are the same type of batteries used in new electric vehicles. With the AC drive technology, it offers high performance and low maintenance costs.

PERFORMANCE

1. The brushless AC travel motor features excellent acceleration,

outstanding climbing ability, low heat emission, and is maintenance-free.

2. The CANBUS structure makes communication between all of the machine’s functions faster and more reliable.

3. The operating handle’s picking button is a part of the pallet truck’s standard configuration. This allows the pallet truck to be operated

from the side to increase the efficiency of the picking operation.

4. The pallet truck’s regenerative braking feature prevents it from sliding on a grade.

RELIABILITY

1. The pallet truck frame is made of high-strength steel plates. It is designed to have a long service life in various working conditions.

2. The box-type stamped forks are stronger, more rigid, and impact resistant.

3. Water-proof plug connectors offer protection for all of the cables. This significantly increases the reliability of the end control rider’s

electrical system.

4. The limit switch of the lifting motor eliminates the overflow of the hydraulic power unit. This is more energy efficient and can protect the

power unit’s motor.

SAFETY

1. The end control pallet truck features three types of braking functions, release braking, reverse braking, and emergency braking, for safe operation.

2. The anti-sliding function on a grade ensures a safe operational workspace.

3. The emergency reversing button at top of the tiller protects the operator from being injured in case of an emergency during backward operation of the truck.